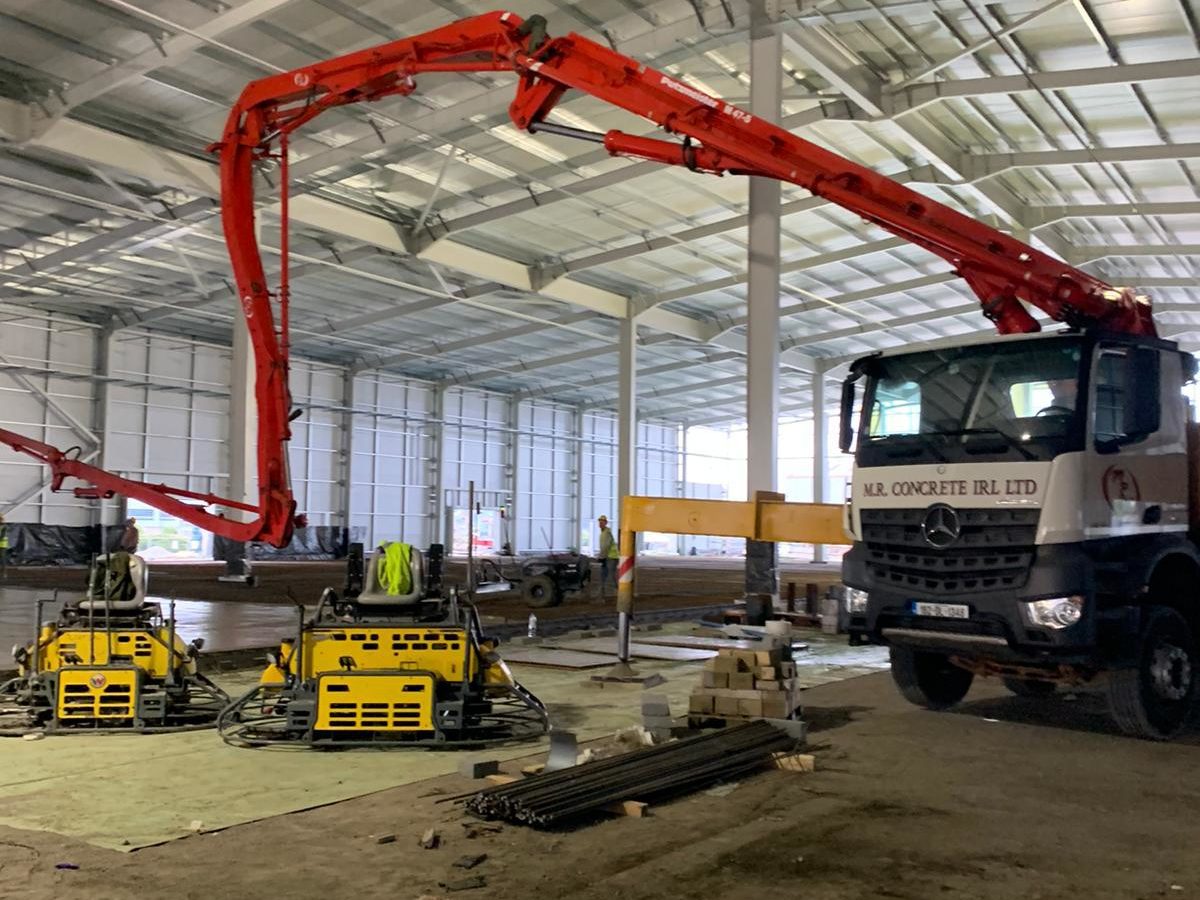

Industrial Flooring

M.R Concrete use of latest high-end technology for industrial flooring practises

Flooring Features:

Laser Levelling

This can be to any fall or crossfall required; the machine will constantly check and control the levels thus avoiding the need for reworking materials. This technology is particularly effective for preparation works for floor slabs, car parks, and road works. Trimble 3D Control System can be used on more complex projects where the digital design data from the design/CAD software can be converted for guidance of the blade control. This has been successfully used by MR Concrete in the construction of playing fields, car parks and roads.

Performing earthworks, smarter, faster, and more profitably is a prime purpose for our customers. The use of lasers in conjunction with our machines will save you contract time, materials, site management time, and most importantly money compared with conventional methods of surveying and checking. Laser technology makes it possible to lay areas in excess of 4500 m² in one day to an accuracy of +/- 5 mm. The materials may be any well-graded soils or hardcore and it is also possible to lay dry lean concrete.

![[M.R. CONCRETE]](https://mrconcreteltd.com/wp-content/uploads/2021/03/newlogo6.png)